About

3D Printing is the practice of creating objects from three-dimensional digital models. Online communities have arisen for 3D printing enthusiasts, including open-source databases where digital models can be downloaded, including Makerbot’s Thingiverse and Defense Distributed’s DEFCAD.

History

In 1983, Chuck Hull[2] invented the process known as stereolithography, which would create solid objects by “printing” thin layers of material on top of one another through lasers and ultraviolet light. Two years later, he founded the company 3D Systems[3] to manufacture 3D printers and other related technologies, specifically for industrial use. By 2000, the Massachusetts Institute of Technology began developing their own 3D printing process, using powders and a binding material.[4]

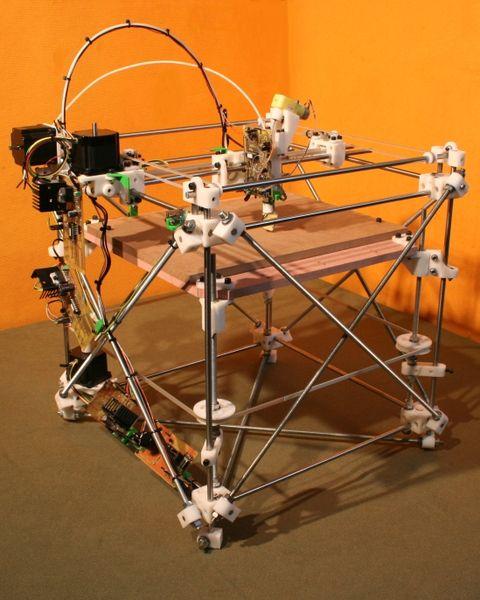

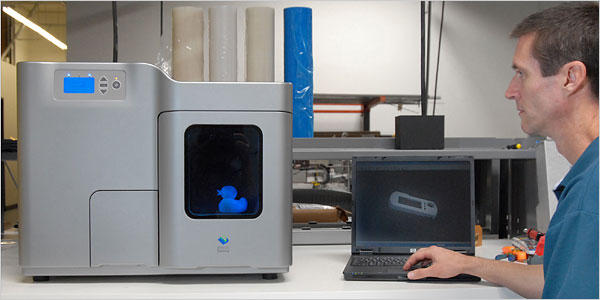

In 2005, RepRap[1] launched, dedicated to building a printer that would replicate itself. By 2006, the prototype Darwin (shown below, left) successfully printed its first piece. Two years later, personal 3D printers began to be developed by Desktop Factory (shown below, right), which began selling their models at $4995 each in 2007.[5]

In 2009, founding member of the RepRap foundation Zach “Hoeken” Smith, along with Bre Pettis and Adam Mayer, launched MakerBot Industries[6], featuring build-it-yourself printers. The company launched on March 15th, 2009[7], offering a kit containing the pieces to build their first printer model, the CupCake CNC, for $750. Approximately a month later, the laser-cut design files were made freely available on the Thingiverse[9], allowing anyone with access to a laser cutter to build their own MakerBot for free.

Online Presence

The 3D printing marketplace and community site ShapeWays[14] was launched on February 18th, 2008. In November of that year, MakerBot launched the Thingiverse[10] website, which served as repository of digital design files for users to share. The website contains designs licensed under the GNU General Public License and Creative Commons, which can be used in a variety of machines including 3D printers, laser cutters and milling machines. In 2010, Thingiverse won an honorable mention in the Digital Communities category at ARS Electronica.[11] On November 21st, 2011, the blog 3DPrinting[15] was launched, featuring news stories related to virtual design and fabrication.

Controversy

On June 4th, 2012 the organization Defense Distributed (DD) was founded by crypto-anarchist Cody Wilson to create an open-source plastic gun. The following month, the organization’s official website was launched, along with an Indiegogo campaign to help fund a project to create a 3D printable gun called the “Wiki Weapon.” Three weeks later, Indiegogo suspended the campaign without comment. DD continued the campaign on its own website and managed to meet its fundraising goal through PayPal and Bitcoin donations.

On December 18th, 2012, Thingiverse removed all listings for firearm and weapons-related designs. The same day, MakerBot released a statement explaining why they began enforcing restrictions on certain types of files:

“MakerBot’s focus is to empower the creative process and make things for good. MakerBot Desktop 3D Printers make innovative products, new tools, models, fashion items, works of art, and 3D things of all types. MakerBot’s Thingiverse website is designed to be the best place to get and share downloadable 3D “Things.” Thingiverse’s Terms of Service state that users agree not to use Thingiverse “to collect, upload, transmit, display, or distribute any User Content (ii) that…promotes illegal activities or contributes to the creation of weapons, illegal materials or is otherwise objectionable.” If an item has been removed, it is because it violates the Thingiverse Terms of Service."

Defense Distributed reacted by launching the website DEFCAD[13], an alternative to Thingiverse where users can share digital designs for controversial objects like firearms and explosives. The website hosts all files believed to have been removed from Thingiverse and those submitted by users for the Wiki Weapon project.

Highlights

MineWays

Mineways is an open source 3D rendering software program developed by Eric Haines which allows Minecraft players to export their constructed worlds and print them via Shapeways.

MakerLove

MakerLove is a website where 3D print hobbyists can download and test out various adult toy designs.

R/C Transformer

Transform Robot is a 3D printed robot engineered by Brave Robotics that transforms from a remote-controlled car into a walking robot with a wifi camera, headlights and an armside dart shooter.

3D Photo Studio

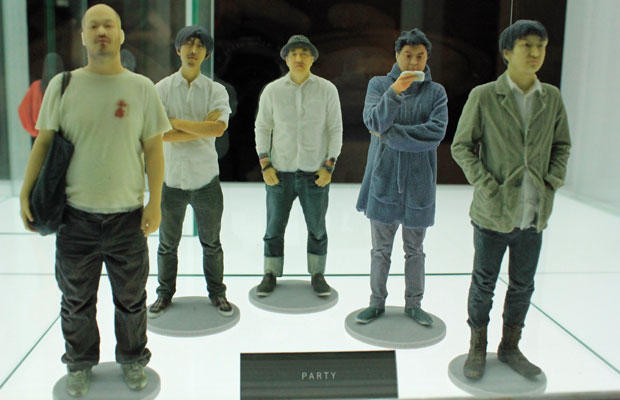

Omote 3D Shashin Kan is a 3D portrait studio located in Tokyo, Japan that uses a handheld scanner to produce a three-dimensional scale model of the model’s entire body, which is then sculpted into a intricate plastic figurine.

Prosthetic Limbs

As early as September 2010, Scott Summit (shown below) of Bespoke Innovations[31] began investigating the feasibility of 3D printing prosthetic limbs for amputees.[32] Although the company has yet to produce a complete prototype, it began offering custom-designed, 3D printed coverings known as Fairings which can be placed over standard prosthetics for extra support. Bespoke’s Fairings have been featured on several news publications for their innovation, including Bloomberg Businessweek[33], Make Magazine[34] and the Telegraph.[35]

In August 2012, 3D printing company Stratasys released a case study[36] of a toddler named Emma (shown below) who had been using a 3D printed exoskeleton known as the WREX[37] (Wilmington Robotic Exoskeleton Arm) to cope with her arthrogryposis multiplex congenita (AMC), a congenital disorder which limits one’s joint and muscle movement. While the WREX was at first made out of metal parts, designers Tariq Rahman and Whitney Sample of the Alfred I. duPont Hospital for Children figured out a way to 3D print a lightweight version for Emma, allowing her to use her arms.

Car

In November 2010, mechanical engineer Jim Kor unveiled the first prototype of the Urbee[38], a fully 3D printed automobile with a hybrid engine that runs 200 miles per gallon on the highway and 100 miles per gallon in the city. Kor’s design was featured on Wired[39] that month. In February 2013, Kor announced the Urbee 2, a three-wheeled vehicle designed for two passengers.[40] Kor is also hoping to keep the vehicle’s safety up to the standards of the 24 Hours of Le Mans[41] race reputed for its intense technical scrutiny.[42]

Human Stem Cell

In February 2013, Six scientists in the United Kingdom and Scotland successfully printed human stem cells with a “valve-based cell printer” that uses bio-inks to fabricate groups of viable stem cells that retain their ability to become any type of cell in your body.

Bionic Ear

Also in February 2013, a group of engineers at Cornell University began working on a 3D print of a functional human ear using gel made of living cells.[28] On May 2nd, 2013, a separate group of researchers at Princeton revealed a second 3D printed ear[29] made of calf cells, hydrogel and a coiled antenna designed to enhance one’s hearing above human levels. However, it is unknown when this type of bionic devices would actually become feasible for a human transplant.[30]

Firearms

Following 2012’s controversy with Defense Distributed over the creation of a 3D printed gun, Vice released a documentary about Cody Wilson and his company Defense Distributed, where he discussed his motivations and hope for his designs. On May 3rd, 2012, Defense Distributed[21] revealed photos of a functional, 3D-printed handgun known as The Liberator[22], made almost completely from 3D printed material with the exception of a nail used as a firing pin and a six ounce piece of steel so it could be picked up by metal detectors. On May 5th, Defense Distributed uploaded the first video demonstration of Cody Wilson firing a .380 caliber bullet using the Liberator (shown below). Later that same day, the video was featured in a Forbes[22] article detailing the test firing, followed by similar reports on The Verge[23], Engadget[24], TechCrunch[25], the Daily Dot[26] and CBS News[27] on the next day.

Food

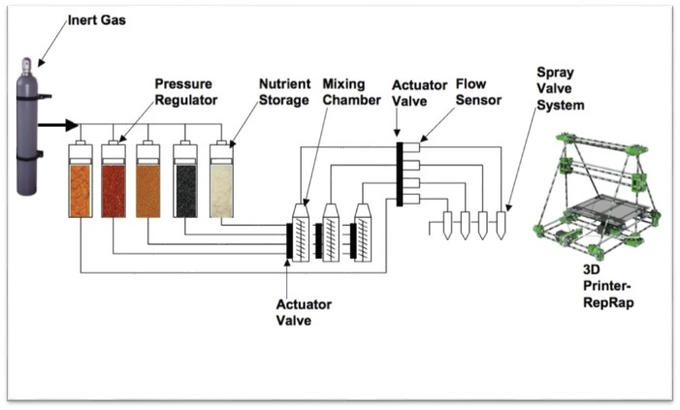

On May 21st, 2013, Quartz[43] reported that NASA has granted Systems and Materials Research Corporation (SMRC) a six month, $125,000 grant to create a prototype of “universal food synthesizer” using the 3D printing technology. Envisioned by American engineer Anjan Contractor,[44] the ambitious project aims to synthesize food with powders and oils containing basic nutrients, the feasibility of which has been previously demonstrated through his prototype open-source machine capable of printing layers of chocolate (shown below).

According to Contractor, the goal is to create 3D-printed food for long distance space missions that would require a shelf life expectancy of more than 15 years, such as human excursions to Mars, as well as to combat world hunger.[45] Though the 3D Pizza project is said to be in conceptual stage, Contractor told Quartz that the printing process will consist of several phases, beginning with the dough layer which would be simultaneously baked by the hot plate underneath, followed by a powdered tomato base layer mixed with water and oil and a protein layer filled with nutrients from animal, milk or plant bases.

Search Interest

External References

[2]Wikipedia – Chuck Hull

[3]Wikipedia – 3D Systems

[4]MIT– What is the 3DPTM Process?

[5]New York Times – Beam It Down From the Web, Scotty

[7]MakerBot – Hello World!

[8]MakerBot – CupCake CNC Kit

[9]Thingiverse – CupCake CNC

[10]Thingiverse – Thingiverse

[11]Makerbot – Makerbot and thingiverse at ars electronica

[12]Indiegogo – WikiWeapon

[15]3DPrinting – 3Dprinting

[16]MineWays – Real Time Rendering

[17]MakerLove – Free Sex Toy Designs for Your 3D Printer

[18]MakeZine – Best of 2012 3D Printed Objects

[19]VentureBeat – First ever: UK scientists use 3D printer to print human stem cells

[20]PetaPixel – Japanese Portrait Studio Creates Tiny 3D Sculptures Instead of 2D Photos

[21]Forbes – This Is The World’s First Entirely 3D-Printed Gun (Photos)

[23]The Verge – First 3D-printed gun fired on video, blueprint files available to download

[24]Engadget – The Liberator, the first completely 3D-printed gun, gets test-fired (video)

[25]TechCrunch – What You Need To Know About The Liberator 3D-Printed Pistol

[26]The Daily Dot – Watch the first-ever 3-D-printed gun firing

[27]CBS News – “Liberator” gun made with 3D printer fires first successful shot

[28]MedGadget – Cornell Bioengineers 3D Print Replacement Ears

[29]Engadget – Princeton crafts a 3D printed bionic ear with super hearing, creepy looks

[30]Wired UK – Study: 3D-printed ear made from calf cells and silver ‘hears’

[31]Bespoke Innovations – Home

[32]New York Times – 3-D Printing Spurs a Manufacturing Revolution

[33]Bloomberg Businessweek – How About Them Gams: 3D Printing Custom Legs

[34]Make Magazine – Bespoke Custom 3D Printed Prosthetic Coverings

[35]The Telegraph – Custom designed prosthetic legs built using 3D printer

[36]Stratasys – Medical Case Studies: 3D printing helps save lives

[37]Jaeco Orthopedic – WREX– Wilmington Robotic EXoskeleton

[39]Wired – 3D-Printed Hybrid Uses Sunlight, Ethanol or Gas

[40]Wired – 3-D Printed Car Is as Strong as Steel, Half the Weight, and Nearing Production

[41]Wikipedia – 24 Hours of Le Mans

[42]24 Heures Du Mans – Technical Inspection.

[43]Quartz – The audacious plan to end hunger with 3-D printed food

[44]H2M – Anjan Contractor

[45]The Daily Dot – NASA gives grant to fund 3-D printer for pizza